Sicher im Galvanikprozess.

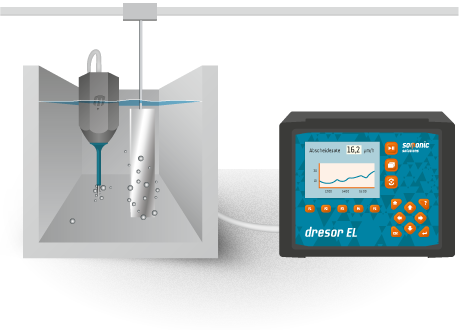

The rod sensor will be immersed into an electrolyte where metal is deposited (in-line measurement). A probe is screwed to the tip of the sensor rod. On this probe as well as on the product metal deposition takes place simultaneously. As conditions on the sensor and on the plated product are very similar, the deposition on the goods is well reproduced by the sensor.

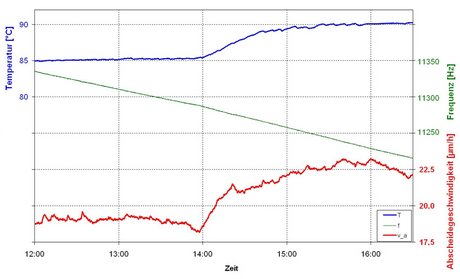

The mass of the sensor rod increases by metal deposition on the probe. This change in mass is measured by an oscillation sensor. Measuring its resonance frequency, the mass resp. the thickness of deposition on the sensor probe is calculated in real time. Using the trend of thickness the deposition rate is continuously calculated. In addition, the current efficiency is measured on-line in electroplating processes.